The second episode of the post-war Kamisoli period: Japan's kamisoli material (Obisteel)

Kamisoli Club representative Yasuoki Takeuchi contributed

As for Obigane, which is used for beard sledges, the relationship between a Japanese sword and the world's kamisori comes out of the surprise.Although it is unfamiliar, the origin of the word 'Masamune' and so on, Gyokagane, which is a material for Tamahagane, used the true sand iron produced in the Sanin region of Shimane Prefecture, which was made from the traditional Japanese steel manufacturing method, and from that time, the sword craftwork of the time was built with a skilled technique with a skilled technique.The gravel itself is part of the granite of the region, with a 1 % of which is true sand iron.The mining method used to scooped a monkey from a sand iron that had been deposited in a river.It was called a specific weight method, and it seems that this style of kosho came to be called "dojo kosaku" (a method of taking a scoop to the people) inIt was originally a sand iron taken from the soil, and it seems that the geisha in Edo seem to have misheard of it.At present, magnets are used to adopt magnetic senting methods using magnets.In this way, "Tamahagane," which is used in the form of "tatare mills," is now mass-produced in the form of "kamisori" in a different manufacturing process.It is called YSS Yaskhagane, and it is also used as a material for the cucumisoli, which is called YSS Yaskhagane, which is produced by the YSS Yakahagane, which is produced by a high level steel manufacturing technique with less impurities, which is a small amount of sand-sand iron.

The Hitachi Metals Co., Ltd. (Hitachi Metals Co., Ltd.) Yasugi, Shimane Prefecture, is ferrous of granite

Fudeperson, April 23, 1985

April 23, 1985: A photo was obtained at the Birchard coal mill located in Yokota Town, Shimane Prefecture.

https://www.hitachi-metals.co.jp/tatara/index.htm

The story of Takatta

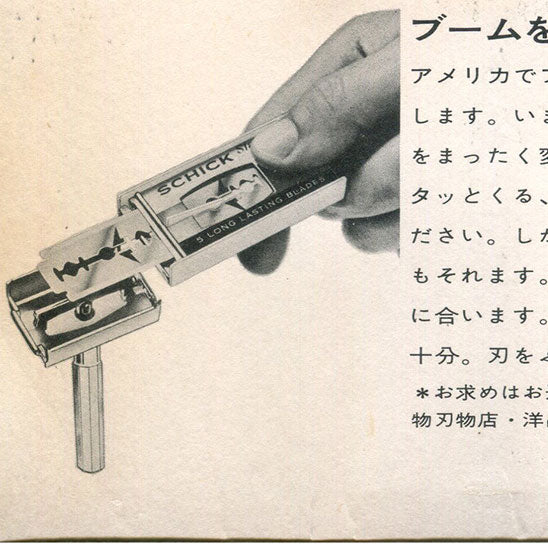

At the time, it is said that about 20,000 tons of steel are used in the world for a year to be used in the world for a year due to the growing demand for the pheasis in the high consumption society.Among them are Gillette, Sick, ASR, India's Malhotra, and Wilkinson, the U.K. ` s most of the company's companies.It is also clear that the consumption of capysol is increasing as well as developed countries in the United States and Europe.As the materials of the old sword are now used for a razor for a kamisori, and Japanese cutting edge steel has been recognized by the world's canirimakers, the current supply of Hitachi Yasquijagane occupies approximately 65 % of the total shipping amount to the world's total casisoli manufacturers.Subsequently, there is a Swedish company of Sandbik and Britain's Brithee Steel, but the gap is not shrinking.Steel, which was produced in Japan, was exported to the world, and was relanded as a finished product (such as "thick" and "Gillette"), and many Japanese people loved it.With domestic products such as automobiles and home appliances surpassing foreign products, only the American products have been overwhelmed by the American products, and the market share is more than 60 percent.This situation is an exceptional case in our country's trade structure.

I asked the person who was directly involved in the spread of Yasaki Hagane in Japan.The answer is a solid homogeneous and stable supply, and even more services are likely to be the cause of the answer.Hitachi Metals also asked the manufacturer of a kamisoori manufacturer in Seki City, Gifu Prefecture in the 1960s, to sell the blades with the name "Sanblades", but the result was that they were pulled out.This is because some unexpected problems have emerged as materials makers.After redeparting as a material manufacturer, the company began trading with Gillette in the U.S. since its establishment in the U.S.The efforts of Mr. Kenji Takitani (former vice president of Hitachi Metal Co., Ltd.), who were recalled at the time, have improved the quality of the products by the time they are used as a sophisticated semiconductor part from the yasykhagane for a kamisi wood for the sake of the sake of the sake of the sake of the sake of the sake of the sake of the sake of the sake.Demand for premium steel, which is derived from the blade of the Camisoli, is becoming an advanced information society, and there is no company that can confront the corporate strategy of the Hitachi Metals Co., Ltd., which has been focusing on the niche market and has been building the company's existence and superiority in the midst of the steel industry, which seeks to expand its use and expand its use in today's M&As and other acquisitions.That is the reality of today.

From the 1960s to the 1970s, it was the reconstruction period of the Japanese economy.In the meantime, in the retail business, Daiei, a department store based in the department store, had the hegemony of sales on the scale of Daiei, a department store chain, and after the transfer of power to the retail market, the consumption pattern of the retail industry has changed drastically.On the other hand, many Japanese companies, such as automobiles and home appliances, have been abroad to earn foreign currency, as Japanese exports have been hit by the drive.The Japanese field samurai (Samurai spirit), which relied on the mother country after the war, became one of the foundations of the economy, and became the economic power.The Hitachi Metals were never an exception.In December 1963, a small 37-year-old employee made a visit to Gillette, the company's largest Camisoli manufacturer, under the leadership of President Ryuichi Nakamura.After that, he maintained a deep relationship of trust and encouraged the development of the best materials.In April 1971, after exerting the business as a material manufacturer, the company started trading with the Sick company, which led to the direct payment of a kami-sori (covering) materials to the world-class Kamisori-sha companies such as Wilkinson, the United States, ASR, India's Marhotra, and others.He was a 36-year-old man who lived alone in the U.S. and had a branch in the U.S. for 11 years in the United States, and his achievements were remarkable.When he returned to Korea on June 21, 1974, he was reluctant to leave the 700-name, including the employees of the local corporation.This is the man's roman, and it is also a touching drama.It can be said that he was a standing actor who built a part of Japan, a trade nation that is today.In a conversation with Mr. Kim, he always says, "This is a shade of good material and not only a success story that we have acquired by ourselves."He joined the University of Tokyo, and is Hitachi Metallic Man who has a career in the second generation of Fulbright's second class.I learned a lot from Mr. Kenji Takitani for more than 30 years, and he has learned a lot from him.It was limited to Mitsuhide.

Hitachi Metals Company, established in the suburbs of New York

Kenji Takiya, 46, at the opening party

However, in the process of producing the blade of a kamisoli, there are no big changes in the manufacturing process for each company, but in the manufacturing process from Obikane (unconventional, grilled, grilled, cutlery, coating), the production method of each type of material, such as material, is different from each company.It is a tasting and patent right.Some of the examples are based on a stainless steel exchanger in 1956, cornea processing of the 1961 cutting edge, ceramic cornea based on the three layers of 1974, and two blades from Wilkinson, both from the UK in 1972, and a double blade to the skin from 1972, and a lubras to the skin in 1986.In 1994, the first sale of the guard Kamisori was made by the Feather Company of Japan, and in the following year, a familiar protector was released by the American Six-Thick Company.In the last 10 years, three blades, four blades, five blades were sold one after another, the domestic seals were beheaded, American thick, and Gillette were beheading the front.During this period, the blade was only 35 years short from the double-edged blade to the five-blade blade.As a matter of course, products have become more expensive and more secure and more secure, but at the same time, prices have increased several times as well.Therefore, the cost of development has become an astoniable amount of investment compared to a single blade or a double-edged era.This trend is a strategic transit point for manufacturers, and they are reflected in the improvement of business performance.

Thanks to Chairman Kohlman M. Mockler (CEO) at the Boston Gillette headquarters in Boston.

At the end of the book, he has been in charge of the material for many years and has been very active in this field, and in the case of the Camisoli, Yoshihiro Honda, who has been called by the nickname of Mr. Kamisoli, is an expert in the manufacturing technique of wearing armor.With the presence of the clan, and by hardship and hardship, the YSS Hitachi Yiskehagane has been spread to the world by 65 % of today's market share, and his contribution is huge.Furthermore, in 2000, he was promoted to president of the company's headquarters, and he must be praised by many shareholders for his achievements in the six years of pitch-heated spiral before he became president in 2006.There is a kamisori as a finished product on the side of the building.and when you look at it, take it, and when you use it, what do you feel? How would you evaluate the value of this casmie?In fact, the materials makers and the people who work in the company have seen a number of people who are taking serious efforts to innovate.In this sense, the relationship between good and good is the relationship between trust and trust born in the belief that good quality is the best."There is no border," the meaning and weight of the words, which were used by Kim and his real father during the period of liberalisation of the Kamiseoli in the 1960s, came to the back of the brain.By accident, the yen's appreciation against the dollar from 360 yen to 115 yen has progressed, but this has also been a major factor driving the market to internationalization, which is now the largest in the world.

Hitachi Metals Co., Ltd. (Hitachi Metals Co., Ltd.) at Yasugi Factory, Shimane Prefecture, the author's name: Kinzo TAKEUCHI, Kinzo TAKENOUCHI, Yoshihiro HONDA (at the time), Kenji TAKIYA (former Vice President of the company), and his title of honorific.

July 21, 2000

The head office of Hitachi Metals Co., Ltd., the head office of Hitachi Metals Co., Ltd. (at the time): President Yoshihiro Honda (at the time): Fudeman, Right: Takeuchi Norioki (Kamisori Club)

I visited Hitachi metal Yasuki factory near Yonago airport in Shimane Prefecture for about 15 years. In the vicinity, there are Izumo Taisha shrine, which is famous as the God of marriage. The company has been involved in the business for 30 years, and it is an opportunity to know the consistent production process of the luxury yakisagane, which is the material of the razor and the blade, centering on the son generation of the son, and the present president of the company, and Yoshihiro Honda of the current chairman of the company. Especially, in the cutting edge field of the razor, the supply rate of the strip steel including the domestic feathers and the seal etc.including the domestic feathers and the seal etc.In addition to the overseas razor maker other than the overseas razor maker such as chick, Wilkinson, ASR, etc., has reached far more than 70% of the world market of sb in Sweden. When seeing the display case in the factory, there were already three pieces of blade, four blade, and five blade blades, and the main force was exhibited, and the transition of the time was realized. It is because the world enjoyed the two blade age when it came 15 years ago. In 1967, the company changed its company name to the current Hitachi metal company in 1967. The factory is located in six places across the country, and this special steel company and Yasuki plant have a large scale and boasts about 280000 Tsubo sites along with coastal factories and Yamate factories. Formerly, the main building of the wooden building in Yamate factory was moved to the site of the coast factory and changed into the modern building. On the other hand, a picture of a high mountain in the site of Yamate factory is constructed by the kanayago Jinja shrine, which is the grand deity of iron and steel. Under the eye, there are several factory buildings. And, "Wagyu Museum" which tells the world of Wagyu and the history of the Japanese steel, such as tamakuri and the old name sword which was born from the Tatara method of iron making, is nearby. The director, yasunoyo, was an engineering doctor and was active as a technician at the local Hitachi metal Yasugi plant. And the word that emphasized on the newspaper comes to my mind. In Japan, the amount of crude steel produced in large quantities such as automobiles and buildings is about 12000 million tons per year, but the production weight of the special steel, which is built in the razor material and the information equipment, is low compared to the comparison.

October 7, 2008

Hitachi Metal Corporation

Watch the production of belts such as razor.

In the center, Yasuoki Takeuchi, the vice president of Murayama factory